Zero Liquid Discharge for effective Palm Oil Mill Effluent Treatment

Palm Oil

Cost competitive plants with total pollution compliance for the Palm Oil Mill

Ensuring sustainable and economical Palm Oil Mill Effluent (POME) is a key challenge. Conventional methods of treatment put heavy costs on millers and increase risks in the face of strict environmental regulations. Shachi Engineering offers innovative evaporation technology to solve the present day and future challenges in POME effluent treatment. Millers will benefit from cost-effective operations, guaranteed compliance, and increased profitability from opportunities to monetize the waste.

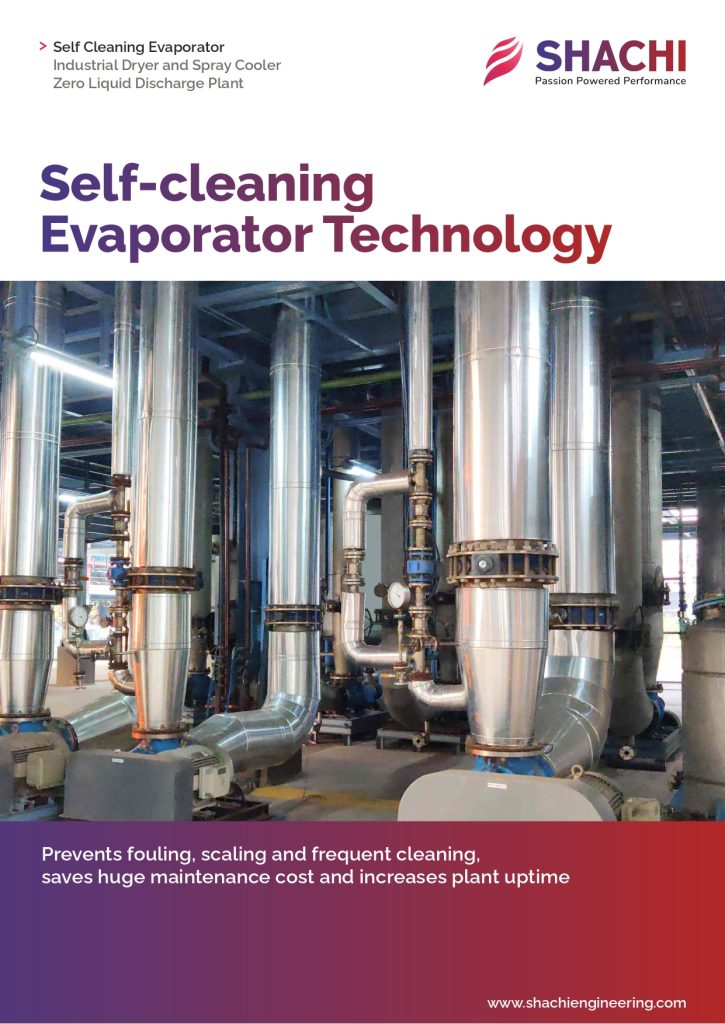

ZLD and Evaporation Technology for Palm Oil

Effluent and Wastewater Treatment

- Eliminates the need for conventional ponding methods

- Meets the required local environmental standards and regulations

- New opportunities from the conversion of effluents to animal feed, fertilisers etc.

- Improved recovery of water, oil from waste

- Energy-efficient, economical and effective solution

Revolutionizing economics of

ZLD & wastewater

treatment in Palm Oil

POME is acidic, rich in organic content and includes oil, water and suspended solid matter. POME releases methane when treated using conventional pond systems. In many cases, the treated effluent from ponding may not meet stringent biological oxygen demand (BOD) limits or discharge colour requirements. The space required in conventional methods are huge and the risks of methane catching fire or from accidental release of wastewater are very high.

Shachi Engineering’s innovative Zero Liquid Discharge Plants using Self-Cleaning Evaporator technology ensure separation of clear water and solid sludge. Further, the sludge can be transformed into valuable by-products. The clear water recovered from ZLD can be recycled and reused in the mills.