Forced circulation evaporators play a critical role in sectors such as food and pharmaceutical industries which process highly sensitive materials. Forced circulation is especially useful when the water has to be removed from certain materials while retaining the core properties of the raw material. Forced circulation evaporators are also used to process liquids that have high viscosity and high solid content.

Working principle of forced circulation evaporators

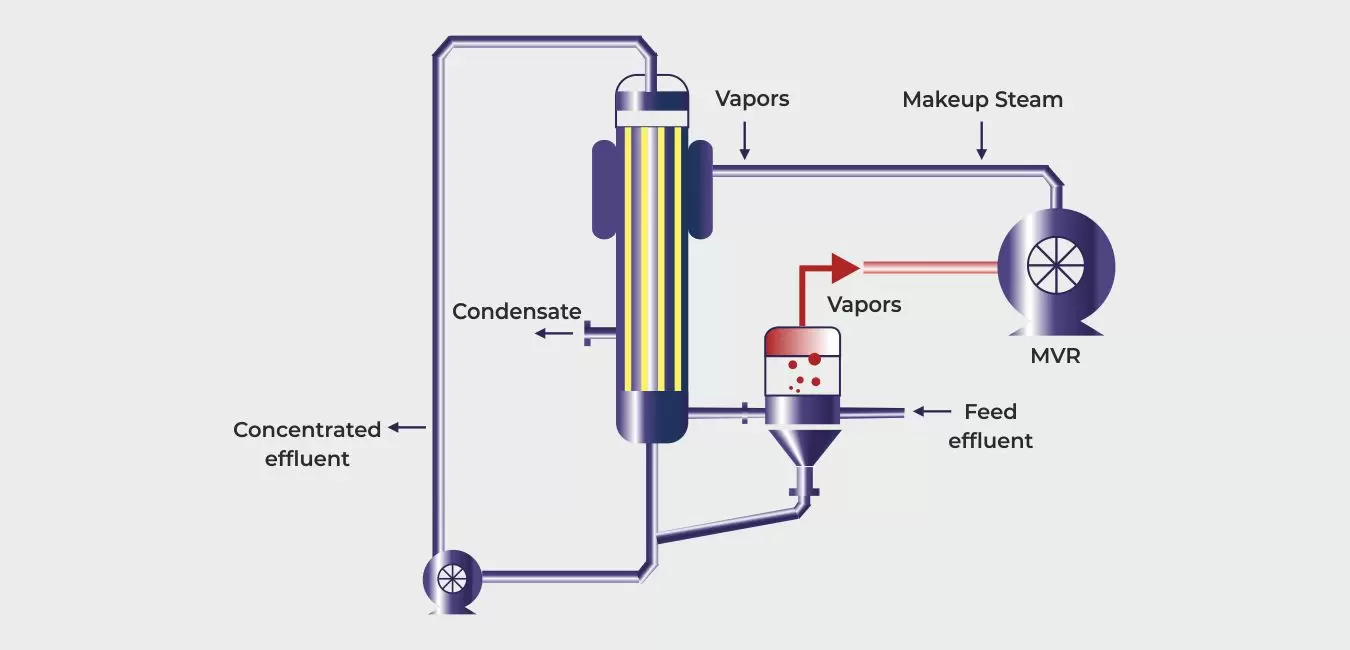

If a liquid boils on a heating surface, its fouling characteristics can cause problems. The forced circulation evaporator mechanism prevents this scenario by raising the boiling point of the liquid. Forced circulation evaporator working involves the liquor being pumped through tubes at high velocity. The liquor goes from the bottom of the cone of the vapour body, through the tubes and then back into the vapour body. When the liquid comes out of the tubes and enters the vapour body, there is a sudden fall in pressure, leading to the flashing of superheated liquor. Hence, evaporation takes place in the vapour body. Forced circulation evaporator working also creates a degree of agitation.

The liquid is maintained at a certain height above the heat exchanger tubes as well as above the vapour body. This helps prevent mass boiling at the tube surface and at the inlet. If the boiling were to occur here, it would lead to fouling of the heat transfer surface due to precipitation in the tubes. Adequate tube velocity is ensured by providing a high circulation rate for the liquid through pumping. This in turn helps achieve the desired heat transfer.

Factors to be considered in forced circulation

Three factors are to be considered when designing a forced circulation evaporator mechanism:

- Liquid-steam separation,

- Exchange of heat

- Energy-efficiency.

In most evaporation operations, heat is supplied by condensation of vapour and water is the solvent. The design of the energetic valve of the evaporator determines whether steam used in evaporation could be recovered and reused or not.

Forced circulation evaporator manufacturers in India

Over the last two decades of its existence, Shachi Engineering has emerged as a leading forced circulation evaporator or natural circulation evaporator as well as falling film evaporator manufacturer in India. A detailed study of your process variables helps us determine the right amount of feed to be introduced, and our expertise helps us to deliver re-circulation at the highest efficiency. Shachi’s Forced circulation evaporators is most suitable for crystalline feed or those containing solids. The circulating pump in our forced circulation evaporator mechanism ensures high speed in the exchange tubes, reduces the number of deposits on the walls and prevents evaporation, thus the risk of over-concentration.

Shachi’s long experience in designing natural circulation evaporators endows it with strong process expertise and enables us to deliver products of world-class quality. Along with an experienced team, we also bring to the table tried and tested designs for forced circulation evaporators as well as falling film evaporators, rising film evaporators or thin-film evaporators, among other solutions for industrial drying and cooling operations.