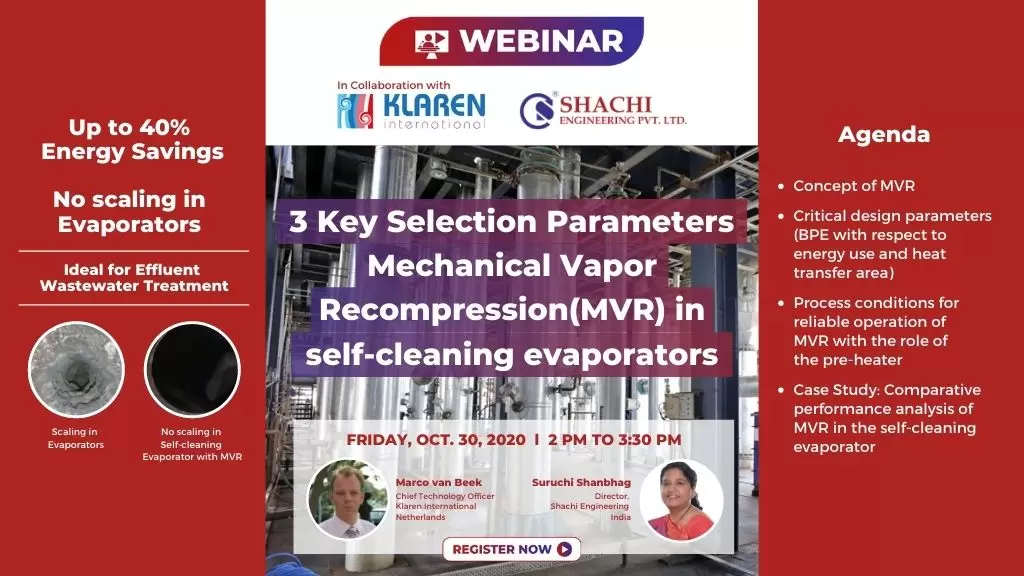

Webinar | 3 Key Selection Parameters for Mechanical Vapor Recompression(MVR) in self-cleaning evaporators| 30th October 2020 | 2.00 noon to 3.30 noon

Save up to 41% energy in evaporators for effluent waste water treatment

Self-cleaning technology has enabled the availability and reliability of evaporators by significantly eliminating fouling. Developed by the Netherlands based Klaren International BV, the technology is now successfully used in India with Shachi Engineering. The technology eliminates fouling and helps process plants to save on cleaning costs and also the downtime required for cleaning and maintenance. However, the benefits of self-cleaning technology do not end here.

With Mechanical vapor recompression, you could save 41% of the primary energy used in self-cleaning process.

MVR involves adding a compressor to the self-cleaning evaporators. The vapor coming from the evaporator is then compressed to increase its pressure and temperature, and can be used in the shell side of the heat exchanger where it condenses. Thus, the energy used in evaporating the latent heat is recovered and the dependence on primary energy is significantly reduced.

When applying self-cleaning process to a multi-effect evaporator, you must choose the effect which generates the most amount of fouling. When this is done, the fouling in that one effect is eliminated, but it remains in other effects, even though its significance is considerably reduced. Mechanical vapor recompression also eliminates this problem.

The present white paper discusses the precise benefits of adding MVR to self-cleaning technology.

The working of self-cleaning technology

The operating principle of the self-cleaning fluidized bed heat exchangers is based on the circulation of solid cleaning particles through the tubes of a vertical shell and tube heat exchanger. The fouling liquid flows upward through the tube bundle of the heat exchanger which incorporates specially designed inlet and outlet channels. Solid particles are fed to the fluid through the inlet channel.

A proprietary distribution system is employed to ensure a uniform division of particles over all the tubes. The particles (mostly stainless steel or ceramic particles with a size between 1 and 4 mm) are fluidized by the upward flow of liquid, where they create the mild scouring effect on the wall of the heat exchanger tubes, thereby removing any deposit at an early stage of fouling formation. After the tube bundle the particles disengage from the liquid in the separator and are returned to the inlet channel through an external down comer, and the cycle is repeated.

To control the amount of particles fed to the inlet, a part of the inlet flow to the heat exchanger is used to push the particles from the down comer into the inlet channel. With the self-cleaning heat exchanger many types of fouling deposits can be effectively handled, whether hard or soft, originating from biological, crystallization, chemical or particulate fouling mechanism, or a combination of all these types.

A comparison of MVR and MEE

Energy efficiency

As stated before, the MVR requires significantly less energy than a MEE. For the latter, the energy consumption in the form of fresh steam is highly dependent on the use of a thermo compressor (TVR), the selection of the entrainment ratio when applying a TVR, the number of effects in the MEE and the configuration of the pre-heater train. For a 4- effect MEE with TVR and an entrainment ratio of 1, a steam consumption of 0.28 kg steam per kg of water evaporation is quite a representative number. Besides the consumption of steam, the MEE-plant with condenser will also use electricity. The electricity consumption is about 0.03 kWh per kg of water evaporation. When using a boiler plant efficiency of 75 % and an efficiency for a conventional power plant of 33%, it can be calculated that it takes 73 kg of coal to evaporate 1 m3 of water when using a MEE.

Energy use of MVR and MEE

* per kg water evaporated ** per m3 of water evaporation

A typical MVR with a double stage compressor takes 0.06 kWh to evaporate 1 kg of water. When we assume the same power plant efficiency of 33% to produce electricity, we can calculate that it takes only 43 kg of coal to evaporate 1 m3 of water when using a MVR. So, ultimately, one can save 41 % in the use of primary energy when using a MVR to treat waste water by concentrating it through evaporation.

Case study: Self-cleaning in dye-stuff effluent treatment

The effluent from a dye-stuff manufacturer is characterized by a combination of salts and organic compounds. When concentrating this effluent, the liquid develops a thick and hard deposit on the hottest tube wall which is that of the first effect. Experience has shown that within 250 to 300 hours the evaporation capacity of a 4- effect evaporator is reduced by 50%. After retrofitting the first effect with the self-cleaning fluidized bed technology, the evaporation capacity remains constant over time.

In this typical case, the fouling in the second, third and fourth effect was less significant than that in the first effect, but it had reduced after the retrofit as well. Knowing the strong dependency on the exact liquid composition, the performance for a second evaporator plant of the same client but at a different site with a different effluent composition showed that introducing the self-cleaning technology solved the fouling in the first effect but the other effects still had fouling. Therefore, the evaporation capacity still reduced over time but at a much smaller rate increasing the average capacity and the time between cleanings.Evaporation rate MEE plant before and after the revamp of the 1st effect to self-cleaning

The design of an MVR system depends on two factors: The compressor used in the process and the composition of the liquid being processed.

Compressor performance

The thermal design of a MVR requires careful attention with respect to the compressor performance, the composition of the liquid and the required heat transfer area. The compressor design and selection determines the temperature increase delivered to the vapor and yields the driving force for heat transfer between the condensing vapor and the liquid at the tube side. The higher the temperature difference, the lower the required heat transfer area (HTA). On the other hand, the higher the temperature increase the more power the compressor will consume.

Liquid composition

The required temperature increase will also depend on the liquid composition because specifically salts increase the boiling point of the liquid. This boiling point elevation (BPE) is lowering the temperature difference between vapor and shell. For example, if the vapor from an atmospheric evaporating system is 100o C, the liquid will boil at 108o C when assuming a BPE of 8o C. When the two-stage compressor gives a temperature increase of 16o C, the vapor will condense at 116o C. The driving force for heat transfer then roughly becomes 8 degrees. In case of a single stage compressor with temperature increase of only 8 degrees, no driving force would be left. The required heat transfer will linearly depend on the temperature difference after correction for BPE.

When the BPE is under-predicted, the chosen HTA could become too small affecting the capacity by only tens of percentage points. Since fouling can easily reduce the coefficient of transfer by 50% or more, the formation of scales can just as well have a detrimental effect on the evaporation capacity. Self-cleaning system prevents overdesign and keeps the plant capacity constant.

Factors to consider when adding the compressorsOperating compressors will require some attention of plant operation. When using root blowers, the equipment is more robust and needs less attention then turbofans. Turbofans have fast running impellers with high tip speed that are susceptible to vibration when the impellers get dirty. Monitoring the vibration and stopping the fan in time will prevent larger damages. When taking care of the compressor, experience has shown that MVR units have a good reliability.

Conclusion

So, to conclude, the self-cleaning evaporator using a MVR is the way to go as to save on primary energy when treating effluent and maximizing the potential of the self-cleaning heat exchanger technology.

Get in touch to know more