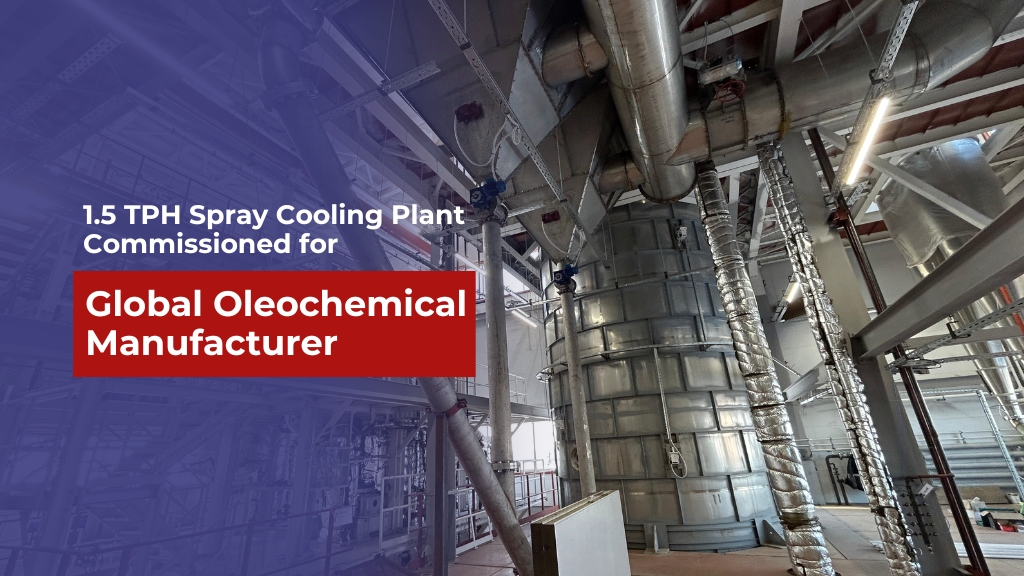

When an existing client returns for a second plant, it speaks volumes about performance, trust, and continuity. After successfully delivering a 2 TPH spray cooling system earlier, Shachi Engineering was once again chosen by a leading Global Oleochemical Manufacturer to commission a new 1.5 TPH Spray Cooling Plant.

This plant was designed specifically for the cooling and solidification of GMS (Glycerol Monostearate), —each known for their specific processing challenges.

Key Highlights:

- Capacity: 1.5 TPH

- Application: Spray cooling and beading of GMS

- Design: Custom-engineered based on previous plant learnings

- Status: Successfully commissioned and operational

Why Spray Cooling for Oleochemicals?

Oleochemicals like GMS require controlled cooling to maintain bead size, shape, and quality. Spray cooling provides uniform particle formation and avoids product degradation—critical for downstream usability.

What Made the Difference?

- Repeat Client Relationship: The same client had earlier commissioned a 2 TPH plant with Shachi, which continues to perform reliably.

- Material-Specific Design: The plant was tailored to suit the flow characteristics, melting point, and cooling behavior of GMS and fatty acids.

- Stable Output: The beading process ensures the required particle size distribution and consistent product quality.

- Commissioning Speed: The project was delivered within the required timeline, thanks to a strong understanding of the process and client expectations.

This new 1.5 TPH plant is now running successfully, quietly supporting production needs while maintaining operational consistency.

Looking to scale up your beading process with a reliable spray cooling system?

Learn more about our Spray Cooling Plants or get in touch for a custom-built solution.